Axial Edge Filters

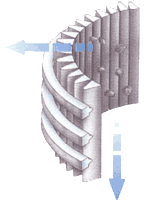

The Auxill Axial Edge Filter is a simple in-line filter for the removal of mixed organic and heavier solids from process liquids. The Axial Edge Filter is equipped with slotted tubes (wedge wire cartridges) or other selected elements. The total inlet surface of these elements is less than the nominal pipe diameter and therefore increasing the velocity in the filter. Because of the increased velocity dirt, solids and organic matter will move forward and collect in the integrated collecting chamber. According to the law of Bernoulli, the water leaves the filter elements at the last section of the elements length, from the inside out. The increased speed decreases at the filter element and water flows out at normal pressure through the outlet. The solids accumulate in the collection chamber, where the differential pressure increases. The collection chamber is controlled by a pressure differential control. At pre set values, the flushing cycle will be activated.

Operation

The filter is equipped with slotted tubes (wedge wire cartridges). The total inlet surface of these cartridges is less than the nominal pipe diameter and therefore increasing the velocity in the filter. Because of the increased velocity dirt, solids and organic matter are moved forward and collected in the collecting chamber. According to the law of Bernoulli, the water escapes the filter cartridges at the last section of the cartridge length, from the inside out. The higher intake speed decreases at the filter cartridge end and water flows out at normal pressure. The solids will accumulate in the collection chamber, where the differential pressure increases. The collection chamber and the flushing valve are interconnected via a radial pipe and a pressure differential control. The differential pressure is measured. At pre set values, the flushing cycle will be activated via a control.

Optimum filter size

The filter size is determined by the throughput, independent of the filter fineness. The filter fineness usually is between 250 µ and 1 mm. When determining the filter size, please assure that the minimum throughput is at least 50% of the nominal throughput. The flow rates indicated in the technical data should not be exceeded. Finer filtration levels are possible.

Advantages

- Easy to install

- Mounted in-line with flanges

- Low pressure loss

- No electric drive

- Limited maintenance.

- Automatic flushing

- Any mounting position

- High solid concentrations are possible

- No moving parts

- Axial Edge Filtersection

Applications

- Cooling water systems & Water intake systems

- (Pre-)filter in process streams

- Waste water effluent polishing

Installation

The Axial Edge Filter does not need foundation. It is flange mounted in the main pipe system, without any additional support. The filter can be mounted in either horizontal or vertical position, the flow always leading downwards. Shutoff valves for the main water inlet and outlet have to be provided for. A bypass line should be installed for maintaining the flow when filter operation is stopped. The purge water line must have an inclination and flow into an open channel, immediately downstream the flushing valve. Installation of risers, reducers or elbows in the flushing water line must be avoided. Upon receipt, the Axial Edge Filter is ready for installation, except for flanges (to be screw-fastened to the filter) and wiring between filter and electrical control panel. After having carried out these steps, the filter can be set into operation.

| Flow rate | Type and intended use of liquid |

| Chemical composition of liquid | pH value |

| Size, type and nature of solids | Solid contents |

| Operating pressure | Admissible pressure drop |

| Required filtration fineness | Operating temperature |

| Voltage | Pre-cleaning filter |

|

|

||||||

| type | capacity | in/outlet | L | K | C | weight |

| (m³/h) | (DN/PN10) | (mm) | (mm) | (DN) | (kg) | |

| 140-100-3-27 | 45 | 100 | 650 | 150 | 32 | 29 |

| 140-125-4-27 | 60 | 125 | 720 | 160 | 32 | 38 |

| 140-125-3-43 | 95 | 125 | 768 | 160 | 40 | 40 |

| 140-150-4-43 | 125 | 150 | 725 | 180 | 50 | 50 |

| 140-200-5-43 | 195 | 200 | 940 | 210 | 65 | 76 |

| 140-200-6-43 | 250 | 200 | 1000 | 245 | 65 | 78 |

| 140-250-4-61 | 315 | 250 | 1290 | 245 | 80 | 109 |

| 140-250-5-61 | 395 | 250 | 1215 | 240 | 80 | 106 |

| 140-300-6-61 | 500 | 300 | 1420 | 270 | 100 | 138 |

| – subject to change without prior notice / please ask for dimensional drawings – capacity related to water at 20 ºC and a 300 filter element – other sizes and higher capacities on request |

||||||

| Housing | |

| Material | Carbon steel |

| Optional | RILSAN® coating (chemical resistant), RVS 304, RVS 316L, Titanium or other alloys |

| Filter elements | |

| Sizes | >200 µ (smaller available, but will reduce capacity) |

| Material | RVS 304 |

| Optional | RVS 316L, MONEL® or other alloys |

| Valve | |

| Type | Butterfly, standard makers selection |

| Material | Selected for the purpose intended |

| Seals | Selected for the purpose intended |

| Optional | Motorized valves, ball valves, pneumatic pinch valves |