CINC Centrifuge technology

Cinc Solutions’ proven, patented technology, combined with their dedication to liquid processing, leads to their success in a broad range of applications worldwide. Constant research and development at CINC Solutions is combined with customer feedback to continually improve and advance our annular centrifugal contactors. Their design team develops the most dynamic, cost-effective, and reliable liquid-liquid centrifuges available. Ongoing efforts to improve existing designs and exciting new developments like their cGMP line demonstrates CINC Solutions’ commitment to remain on the cutting edge of centrifuge technology. Their centrifuges are available in a variety of sizes, ranging from R&D and pilot to full production scale units, with flowrates ranging from 0.5 gpm to 200 gpm (1.9 Lpm to 757 Lpm). Process R&D results, obtained with the CS-50, are easy to use for scaling to full capacity models. Multiple units can be employed in a parallel or series to handle larger flows or for multi-stage processes.High separation efficiency at longer residence times at 100-1000 G’s provides better process control for improved yields, faster processing, low in-process inventory and minimal waste.

Operation principle

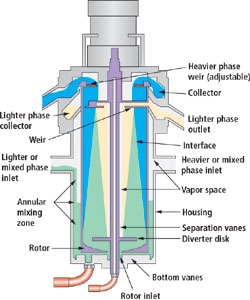

The CINC Solutions’ liquid-liquid centrifuges operates both as separator and contactor, which makes it a valuable tool in numerous types of processes. Its unique, patented design provides mixing and separation in a single, compact unit.

Two immiscible liquids of different densities are fed to the unit and are rapidly mixed in the annular space between the spinning rotor and the stationary housing. The area above the liquid levels is vent area. For separation applications, a low-mix option is employed to reduce liquid shear in the annulus.

The CINC Solutions’ self pumping rotor is divided into four vertical chambers, which are dynamically balanced by the pumped liquids. Once trapped in a quadrant, the mixed phases are rapidly accelerated to rotor speed. Separation begins as the liquids are displaced upwards at continual pumping.

The separating zone extends from the diverted disk to the weir, providing a residence time for the liquid-liquid interface to form and sharpen. In most cases the CINC Solutions Centrifuge can process 100% ratio changes without further adjustment. This capability is due to a large dynamic interface zone that allows it to shift significant distance without loss of separation efficiency.