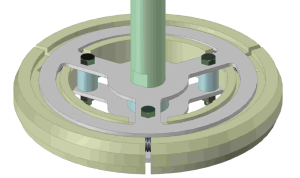

Automatic Disc Scraper

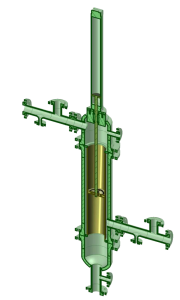

The ADS Filter is a self cleaning filter which filters solids out of fluid. The filter materials you can choose from are perforated plate, wegde wire element of our new alternative: sintered metal.

Applications

Chemical industry

- ammonia

- solvents

- softening agents

- glycols

- adhesives

- chemical base materials

- suspensions

- lye’s

- waste liquids etc.

- washing liquids

- distillation and reaction fluids

- surfactants

- for preliminary and coarse filtering

- upstream of distillation columns

- reactors, flue gas scrubbers

- pumps

- fine filter

- filling plants

- Paint and color industry

- varnishes

- dispersions

- coatings

- tar products

- agents

Mineral oil industry

- oils

- greases

- solvents

- waste oils

- diesel oils

- lubricating oils

- heating oils

- heat trasfer fluids

- reclaimed oils

- salt water

- lime processes

Car industry & metalworking

- degreasing baths

- cooling liquids

- lubrication liquids

- greases

- cooling water

- washing and scrubbing water

- process water

- water from cutting processes

Food industry

- sweets

- dairy products

- fats

- flavors

- concentrates

- treacle’s

Plastic industry

- base products

- PVC- and PU-pastes

- rubber products

- sillicones

Paint and color industry

- varnishes

- dispersions

- coatings

- tar products

- agents

Beverage industry

- wineries (must filtration)

- breweries

- distilleries

Cosmetic industry

- soaps

- fats

- essences

- tooth pastes

Plus many other applications in the electro, optic, pulp & paper, leather and sugar industry.

Features

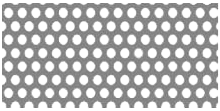

- Filters from 0,5 µ to 3 mm available

- Minimum material quality is SS 316L

- Maximal temperature up to 50 ºC or more (optional)

- High differential pressure up to 5 bar

- Inside – outside filtration

- No product contamination

- Purging by pinch-or butterfly valves

- Taylor made execution possible

- ATEX proff because of complete pneumatic system

- Self cleaning

- Easy installation

- Remote controllable.

Benefits

- No cartridge use

- No waste or disposal of filter cartridges

- Minimal product loss during purging

- No interruption of production process

- Easy to dismount and inspect

- May be used for all kinds of liquid

- Low operating costs

- Solidly built filter housing

- Limited maintenance, uncomplicated and reliable design

- Filtration level 2 µ – 3 mm

- Continuous cleaning of the filter surface ensures minimum pressure drop

- The use of different construction materials and equipment facilitates application opportunities for the filter in any field of industry

- When installed before pumps or other equipment, the filter will extend the life of such components and will prolong the service line of fine filters

- Large flow possible by using manifolds.

Filter opties

Sintered metal

Wedge wire element

Perforated plate

ADS Filter of sintered metal

Sintered metal is a new kind of filter material used with the ADS Filter. It is made of pressed metal powder, for example, SS, titamium, hastelloy or monel. It has a filter fineness range of 0,5 – 200 µ. Where ever filter media or flocculants were used with a filter fineness of < 15 µ, we now have a ecofriendly alternative.

Advantages ADS Filter of sintered metal

- No need of filter media or flocculants

- Low power use

- Sustainable

- Self cleaning

- Low maintenance

- Easy to use

- No process interruption

- Able to work with large flows

- Installed before pumps and other equipment it may prolong their operational life.

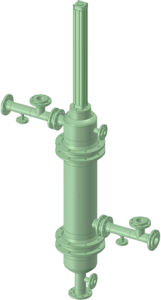

| Specifications ADS Filters | |

|---|---|

| Measurement | 2380 mm |

| Design pressure | 16 bar, higher is optional |

| Test pressure | 24 bar |

| Design temperature | 50 ºC, higher is optional |

| Tank volume | 0,08m³ |

| Weight | 165 kg |

| In,-outlet | DN 150 PN 16 |

| Purge outlet | DN 64 PN 16 |

| Vent outlet | DN 25 PN 16 |

| Rinsing inlet | DN 25 PN 16 |

| Filter element dimensions | D=200mm L=750mm( L=1.000 is optional) |